Breton flute

Breton flute

Breton flute.

Here is a whistle, or rather a diatonic recorder of a style deliberately more

Breton than Irish.

It is intended for the repertoire of the bombard and differs from the Irish

flute by the presence of a subtonic hole, just like the key of the bombard.

The flute is also quite powerful and stable in the low register, which also

corresponds well to the range of the bombard.

It is in D major, unlike the Bb bombard, but in truth a Bb flute would be too

long

and the goal for a training instrument is rather to have a similar finger

spacing to that of the bombard.

The bore is tapered inverted, and the head is removable, allowing adjustment

of the tuning.

The flute is made of three woods, rosewood, boxwood and Macassar ebony for the

body.

It is also decorated with pewter inlaying.

Here is a small video presentation ..

For those who are curious about how to make a flute, here are some pictures

showing

the steps of manufacturing.

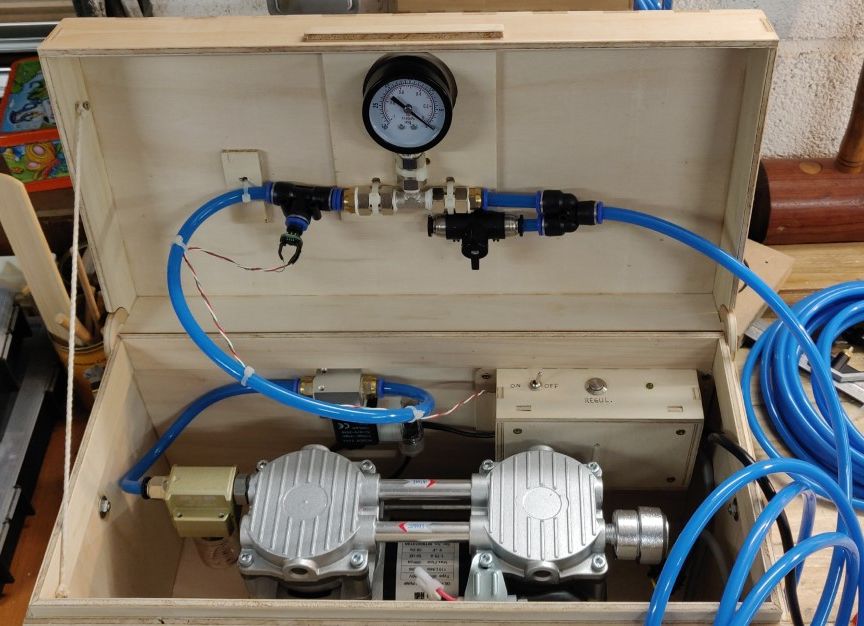

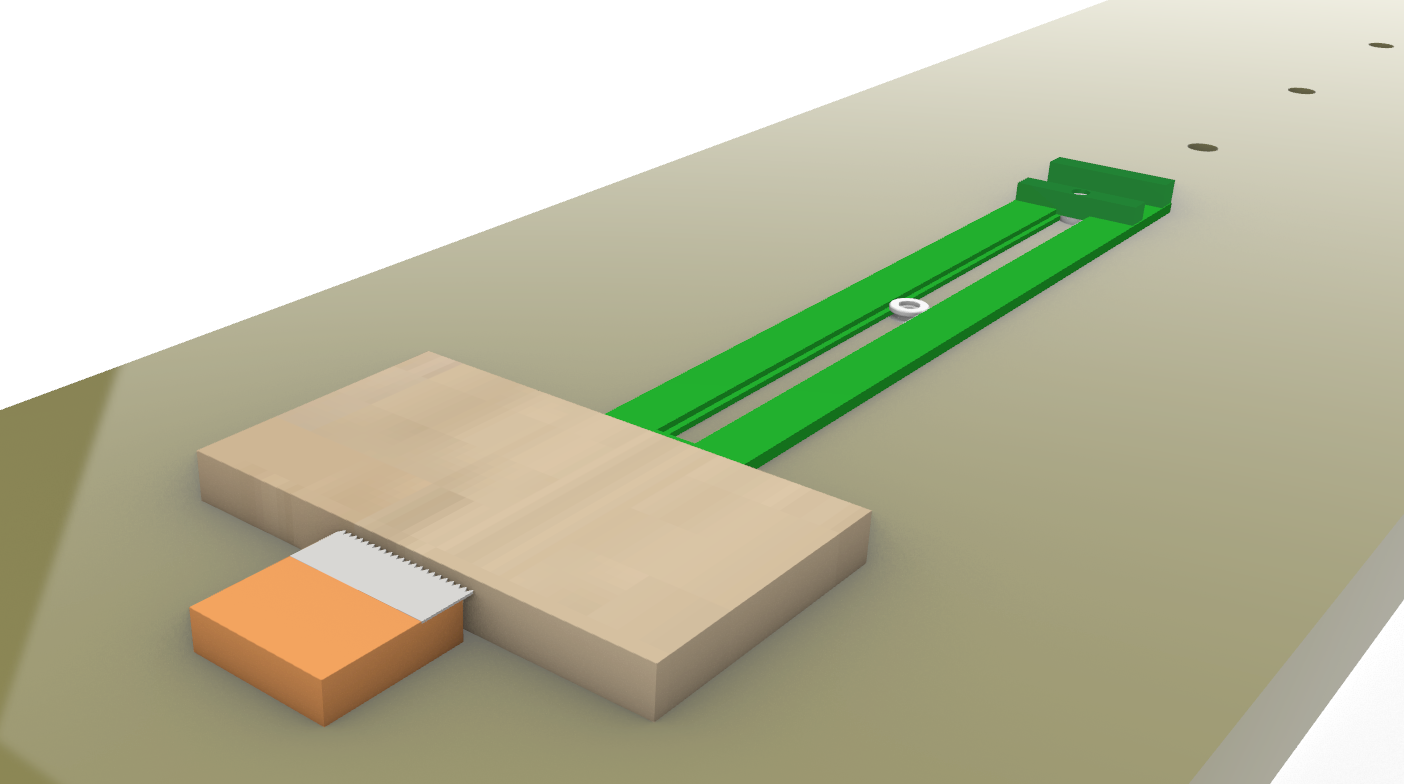

The first difficulty, especially for conical instruments, is drilling and

boring.

The piercing is done in a stepped way, starting with the smallest diameter

from one side to the next, then by successively bigger diameters on a shorter

length, so as to rough out the cone.

Unfortunately, I did not take pictures of this step. It is actually done in

advance, so as to leave

the time for the wood to stabilize and fully equilibrate with the moisture of

the surrounding air.

The first photos show the boring of this flute, ie the shaping of the inner

cone with a tool

called a reamer which has the exact shape of the bore and which allows to

obtain a perfect surface state.

The making of a conical reamer is in itself quite an adventure, and this is

explained in another article.

Older readers comments

Hello from simon