Titanium and Wood Rings

Titanium and Wood Rings

Table of contents :

Titanium / Wood Rings

I have long-sought to improve my solid wood

rings, which are still fragile in certain

species and if they are made thin. The idea of lining them with

metal

is attractive, but it is necessary to find a resistant enough metal that is

well supported in contact with skin.

metal

is attractive, but it is necessary to find a resistant enough metal that is

well supported in contact with skin.

The ideal solution is to use titanium.

Titanium is lightweight, strong, perfectly hypoallergenic, and resist all

kind of corrosion.

It keeps pretty well its polish, its color is a sober grey-silver.

If titanium is a metal with many qualities, it also has unfortunately several drawbacks:

- It can be quite hard to find for the amateur

It is relatively expensive.

It is relatively expensive.- It is difficult to machine to say the least.

- The chips, dust or fine debris are flammable!

After having found eventually some 30 mm diameter titanium rods, my first test

cuts on the lathe have failed. When turning like I would do with aluminum or

brass, the HSS tools become red hot without biting the metal, and carbide

tools, even if they are more resistant, did not perform extremely well either.

When I tried to approach a file on the turning piece, in order to round shape

the angle, as I can do for steel or brass, it is the teeth of the file that

have been machined …

While discussing and exchanging on various forums, the solution was given to me.

In particular, I thank:

- Brian, alias bstanga on homemadetools.net who, after having had difficulties in the machining of titanium, described the machining method that works.

- Daniel, alias calimero54, on the French forum couleursbois.com, who described his method and the carbide tool he used for making titanium rings.

Titanium is really a metal with unusual properties, and one of them is the key to understand the difficulties we can have for machining this metal.

In fact, titanium is a poor heat conductor. The result is that the energy

generated by friction against the cutting tool, instead of dissipating into

the workpiece, dissipates into the tool itself, as it is a better thermal

conductor than titanium. Therefore, even with lubrification, machining

titanium at the usual cutting speeds is a nightmare.

The solution therefore is just to minimize the speed of rotation during the

machining, about 100 rpm, if possible less.

Likewise, the feed must be quite aggressive, so as not to generate unnecessary

friction.

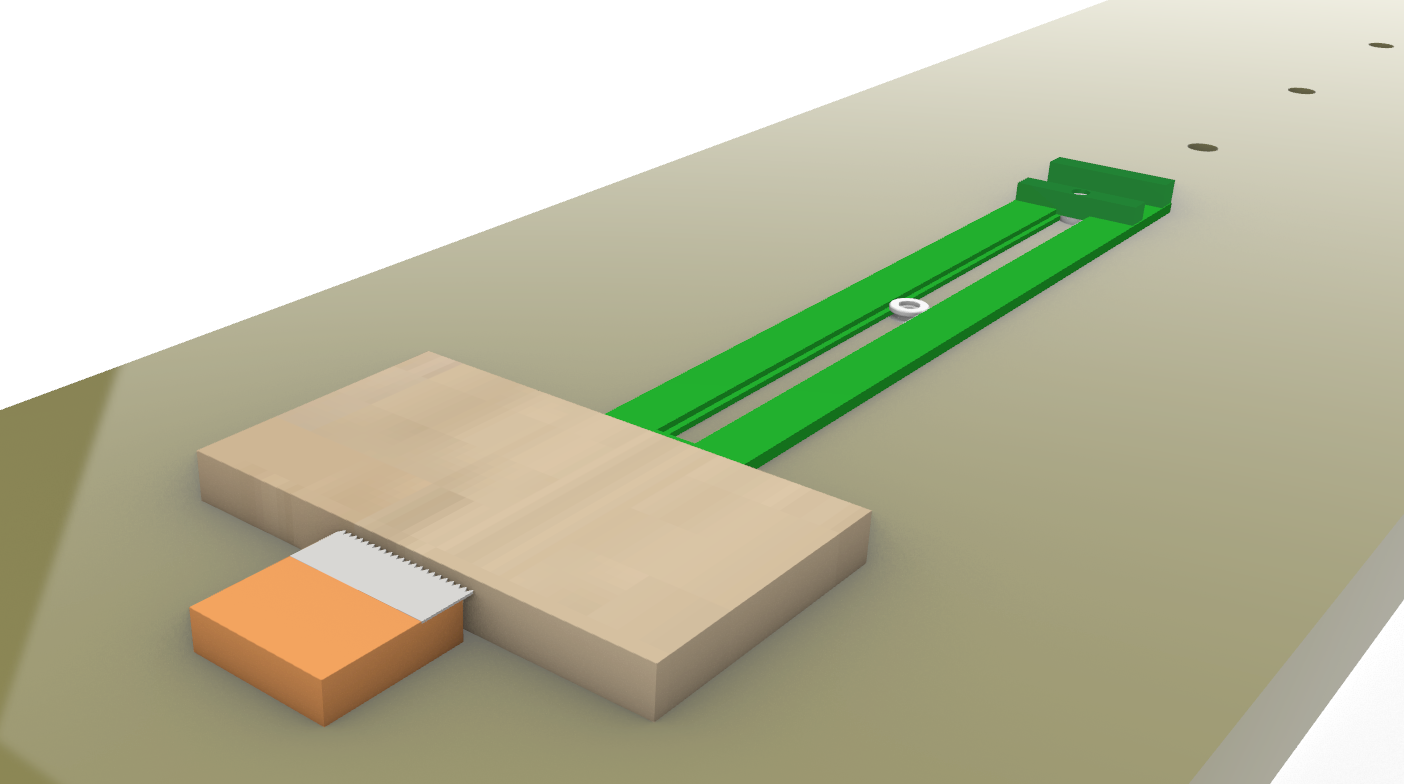

Coming back to the manufacture of the ring itself, Daniel, above described a custom made tool, made out of a solid carbide bar. He can even machine two rings, of two different diameters, in the same titanium section.

I kept the idea of the carbide tool from Daniel, modifying the profile to obtain a more durable tool, but giving up the idea of two rings in the same section.

The same tool can be used to dig the inside of the ring, and to part off the ring. The external profile cutting is achieved using a standard carbide tool, again at low speed.

This way I can make solid titanium rings(photo above, left ring) or mixed wood and titanium ones, as this ring below made out of red sandalwood, CA finish.

In the case of the timber / metal ring, I first made the metal ring to a calibrated external diameter. I then drilled and precisely bored a wood blank to the same inner diameter. I glued the two pieces with epoxy, and I finished the ring using a ring mandrel on the wood lathe.

Some pictures of the process:

1- Left, the tool, shaped on the grinder (green, for carbide).

Right, the titanium rod, 30 mm diameter.

|

2-Close-up on the tool profile. The curve follows the inner diameter of the ring. You can see the nice shavings made with a quite aggressive feed and low rpm. (paradoxal !)

|

3- Digging into the end of the rod, making the inner diameter of the ring.

—|—|—

4- External diameter turning.

|

5- External round shape, profiled with a file, at extremely low speed. Finished up with sand paper.

|

6- Parting off the ring, still with the same tool.

7- Taking back the ring on a mandrel purposely made in a piece of steel stock.Shaping the other rounded external profile.

|

8- On the right, the finished ring. Titanium supports very well buffing.

|

9- The ring on the right is made out of bronze. Unfortunately, it cannot be worn on the finger because of the rapid oxidization caused by the sweat. However, it can be worn as a pendant.

Feel free to leave me comments, either here below, or also on Facebook, or on HomemadeTools.

Christophe

Older readers comments

Hello from bstanga

Hello from jean_michel